Once enacted, the Act would require two-person crews on all freight trains, with few exceptions; cover Yardmasters under Hours of Service; outline a strategy for Amtrak to move away from being “profit” based to being “service” based; add a study of safety impacts of long trains and Precision Scheduled Railroading; require brakes subject to leaking in the cold be pulled out of service; create additional oversight on the failure of PTC systems; direct the FRA to better include labor in accident investigations; deploy a federal standard to reduce blocked grade crossings; add crew size and train length to FRA accident reports; address assaults on bus and transit drivers and operators; and, add a labor member to the Amtrak Board of Directors.

Please click this link to send a message to your US Representative. Time is short as this legislation is due to be considered in the coming days.

Author: paul

Last episode, we heard from two SMART sisters — Lisa Davis and Vanessa Carman — who discussed how they got into the industry, training and mentoring, growing diversity in construction and opportunities for women in the sheet metal trade. In Episode 6, we continue that conversation with two more female leaders and activists in SMART who have taken the lead in creating new opportunities for women in the building trades.

Our first guest is Mechelle McNew, chair of the SMART Women’s Committee and a longtime business manager at Local 464 in Ponca City, Oklahoma. She discusses how she got into the trade, how workplaces have changed for the better for women in the industry and what it was like being the first woman to run for and win elected office in her local.

Our second guest is Leah Rambo, a native New Yorker who serves as the training administrator for Local 28 and has broken new ground for women and minority members in her local. She is also the co-chair of the National Taskforce on Tradeswomen’s Issues. Leah shares her story of coming up in the sheet metal industry, addressing bias and harassment in the workplace, mentoring and female role models, and the importance of SMART doing targeted recruitment and outreach to women and people of color.

Both Michelle and Leah also discuss the important work of the SMART Women’s Committee, including attending the 2019 Women Build Nations conference with a large cohort of SMART sisters, and how the committee helped to draft and organize around a number of resolutions that were ultimately adopted at the 2nd SMART General Convention in August 2019.

In addition, listen for the open mic segment at the end of this episode, where General President Joseph Sellers responds to a question about what SMART is doing in response to protests and rallies for racial justice across the United States and around the world.

Click here to listen to the episode

Since the 2016 election cycle, General President Joe Sellers has focused the Union’s efforts to listen to and address feedback from members on local, state and federal issues that affect them at work. This means being transparent and clear with members when asked to support the candidates who most closely align with our issues.

During the past four years, SMART leadership has met with nearly all the presidential candidates and had meaningful dialog regarding our issues. Many of them, we have found, support the issues of importance to the membership of this Union.

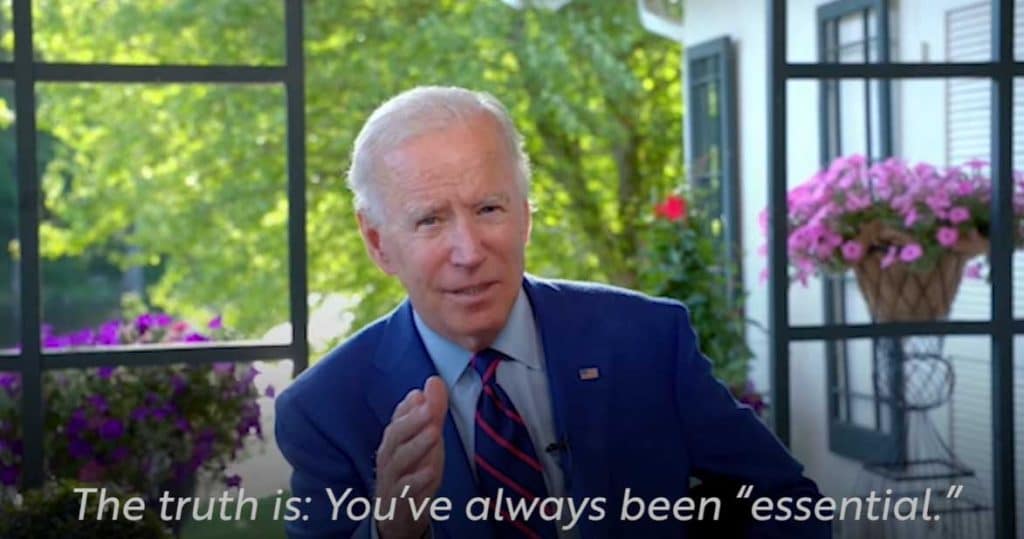

One of these candidates is Vice President Joe Biden. SMART met with Vice President Biden’s team several times, all of them being very productive conversations. Vice President Biden, with a long history of interaction with members in both the sheet metal and transportation industries, is acutely aware and engaged in our issues. His team took what they learned from our conversations and created this video to allow the VP to speak directly to you about the issues you have raised concerns about and his position on them.

The SMART Women’s Committee stands in solidarity with the Black Lives Matter Movement and the countless brave protesters exercising their constitutional rights of speech and assembly to petition our government for a redress of grievance.

The SMART Women’s Committee lends our voices, not only because it is the right thing to do, but because we understand the detrimental effect that such bigoted views have had on our own locals. We not only need justice, but there must be a standard of accountability to be set and upheld.

We cannot be silent in the face of oppression and brutality – we cannot afford to be complicit to mechanisms that seek to attack, divide, suppress, assault, harass, and subjugate our communities.

It is not enough to be against racism – we must be actively anti-racist. We must all work assertively to dismantle systemic racism and heal the generations of trauma that have wounded our country and our communities of color. This is all our work, and our responsibility for what is just and right. We join those seeking to fight injustice – racial, social, gender, and economic – everywhere. The labor movement has long held high these core values.

Just as SMART has been made accountable for the past actions of its members, we call for the same – especially for those who are supposed to uphold the law. Just as SMART is committed to putting measures in place to make sure that all our members can live and work safely and with dignity, we demand a national paradigm shift to repair centuries worth of harm.

We acknowledge that to make such demands are confronting and uncomfortable, but they are necessary. What the SMART Women’s Committee is committed to doing and has been doing is facilitating workshops and providing resources that address these issues. By continuing to work with SMART and General President Sellers, this is the active role we all can play to bridge the gap between inequities in our locals and in our country. We hope that you’ll join us in taking part in these important discussions.

Please: listen to, learn from, engage with and support the POC community. This is a human rights issue; a working-class issue; an American issue – for an injury to one is an injury to all.

Black Lives Matter.

On a crisp fall Saturday this past November, two dozen members of the Local 27 SMART Army turned out to volunteer their time and help install ducts and a new HVAC system at Kiddie Keep Well Camp in Edison, New Jersey.

Founded in 1924 as a “fresh air focused camp” with the mission of providing summertime activities and enjoyment to less privileged children, the camp has now served kids and seniors in Middlesex County for nearly a century.

“I couldn’t find a better day to spend than working here and helping and donating my time with a bunch of other sheet metal workers,” said journeyperson Chris George, who has been with Local 27 for 22 years. “It’s really good for sheet metal workers to get involved in the local community. Sometimes the building trades gets a bad rap. It’s good to show that we care, we give, we donate, we’re a skilled trade and we’re here to help the community.”

Kiddie Keep Well Camp started with only 60 campers and a small staff consisting of a director, several volunteer counselors and a cook. It has grown to serve over 600 children and seniors who utilize its facilities each year, and has served over 50,000 youth during its lifespan.

The camp is unique in that it’s the only camp of its kind in New Jersey and one of the oldest in the nation. It regularly receives referrals from a number of different sources, including school nurses, guidance counselors, principals and government agencies.

Due to its age, the camp has needed unique maintenance and improvements over the years. While its original focus was on recreational activities, it now also serves local communities by providing free dental and health screenings for children.

Accredited by the American Camp Association and licensed by the state Department of Health, the camp includes nine cabins, two pools, an administrative building, a learning center, a library and the health center. To accommodate this important work, the camp building that houses its health facilities, originally built in 1947, was used extensively over the years and was in dire need of a facelift.

Camp President Tom Tighe, who is also a retired United Association official, reached out to his fellow building trades, including SMART SM Local 27, to help renovate the camp and its facilities.

“Local 27 was happy to answer the call in making sure this camp is renovated and in shape for when kids and seniors come for its services,” said Local 27 Business Manager Andrew Caccholi. “The SMART Army has given us an opportunity to be here helping out underprivileged children. We have a tremendous amount of members here working, including apprentices, journeypersons and all the instructors as well.”

Caccholi also lauded the work of Local 27 Training Coordinator John Espinos and Business Rep Tom DeBartolo in reaching out to members via text messaging and Total Track.

“The apprentices look forward to giving back to the community, and they wanted the experience of working on a residential project like this,” said Espinos, who is no stranger to helping the local community work through his work as a Boy Scout leader.

In addition to Local 27 members working to install duct and an entirely new HVAC system, added Espinos, signatory contractors Central Sheet Metal Fabricators and Passaic Metal Products were asked to help with the project and responded by fabricating and delivering donated material to the site.

“One of the biggest problems that all unions have is we don’t do a good job self- promoting ourselves, ” said Debartelo, who also coordinates SMART Army activities for the local. “We give a lot back to the community through donations and projects such as this. Not just our local does this, but all the building trades do this type of work and we want to make sure we are recognized for this.”

Camp President Tighe underscored that the upgrades to the camp’s facilities could not have been done without the building trades in Middlesex County, especially the help from members of Local 27.

“It’s been a godsend,” said Tighe. “We’ve gotten all the labor and 90 percent of the material donated. So thank you to my brothers and sisters at the sheet metal workers.”

As health care workers and first responders across the United States continue to face critical shortages of face masks and other protective equipment, SMART sheet metal locals are collaborating with union contractors to produce and donate metal nose strips for the millions of masks being made by volunteer groups across the country.

The thin and flexible metal strips are critical to custom-fitting the top of a mask to a user’s face, making them more effective, less likely to slip off and more comfortable to wear.

In late March, the Hillery Company, a custom metal fabrication shop located in Groton, Conn., began posting messages on its Facebook page announcing that the company would donate the nose strips to anyone looking to make masks.

“Hillery was asked by a local nurse to make the aluminum strips used on N95 masks so they could sew them in the cotton masks being made by volunteers around the country,” said Hillery employee and SMART Local 40 member Joe de la Cruz in a message posted to the company’s Facebook page on April 6. “I posted a picture showing a small box of strips on March 24th and it has since gone viral.”

Since then, the company has mailed out more than 500 packages containing more than 40,000 metal nose strips.

“We have received requests from hospitals and small sewing groups from every state and Canada,” noted de la Cruz on Hillery’s Facebook page. “This is a grassroots effort and most of the folks asking for the strips are sharing stories about their loved ones going to work without protection.”

With more than 3,000 requests totaling more than 300,000 nose pieces since March 24, requests quickly outstripped the company’s capacity to fulfill and ship all the orders. De la Cruz reached out to leadership of his union for help. The response was immediate – union locals and union sheet metal contractors from around the country were eager to join the effort and effectively begin crowd-sourcing mass production of the small metal pieces.

SMART created an online request form and began publicizing it on social media on April 7. Within hours, the union had hundreds of requests totaling more than 15,000 metal strips from volunteers making donated face masks from Alaska to Florida.

“We are producing high quality masks using Halyard N600 paper, which gives a N99 mask. These are for the high-risk areas of our hospitals,” wrote Constantine of Brookhaven, Georgia, when submitting her request. (N95 masks are rated to filter out 95 percent of airborne particles; N99 masks are rated to filter out 99 percent.)

“I have made 150 so far for our community and have twice that many to go at least!” wrote Stacey in Lathrop, Mo., when submitting her request. “Thank you! This is a HUGE help!”

“So grateful for anything you can offer,” wrote Jonathan of Medfield, Mass., when submitting his request. “We have made 700 masks so far, but pipe cleaners add to production time. We are a non-profit, sewing masks for over 40 groups, including the local police department and fire department, hospitals, doctors and nurses.”

As each request comes in, SMART assigns it to union local near the ZIP code of the request. That local will then work with a union contractor in the area to produce the strips and deliver them to the volunteer or organization that requested them.

Volunteers can order masks at https://actionnetwork.org/forms/nose-piece-request-form

“We want to do everything we can to help and support health care workers and first responders who are on the front lines helping people and savings lives in our communities during this public health crisis,” said SMART General President Joseph Sellers. “This is a great idea that began with one union shop in Connecticut and took off like wildfire. We are now working to scale this up as fast as we can across the United States and Canada.”

The new national framework outlines planning and implementation elements with strong minimum standards, screening policies and the requirement of a comprehensive employer exposure control plan comprised of control measures, symptom checking, social distancing, training, hygiene and decontamination procedures.

To implement a COVID-19 exposure control plan, employers should:

– Designate a site-specific COVID-19 officer at every job site.

– Plan for office staff to have the ability to work from home.

– Training: Train workers with the most recent information on the hazard and control measures, including social distancing, handwashing facilities on site, and how high-touch surfaces are disinfected.

– Screening: Ask workers to self-identify symptoms of fever, coughing, shortness of breath, chills, muscle pain, headache, sore throat, and new loss of taste or smell each day, before the shift, mid-shift, and at home.

– Screen all workers for fever at the beginning of shifts and when they become ill on the job.

– Thermometers must be ‘no touch’ or ‘no contact.’

– Workers with COVID-19 and other workers who have had close contact with those workers should be put on sick leave. Local health departments should be notified. The area where the

sick person worked should be immediately disinfected.

– Ensure affected workers receive paid sick leave as required under the Families First Coronavirus Response Act (FFCRA). The U.S. Department of Labor’s poster about paid sick

leave under the FFCRA should be posted at the workplace. A copy can be found here.

Social distancing: Implement social distancing procedures:

– Create at least 6 feet of space between workers by staging/staggering crews.

– Modify work schedules to stagger work, provide alternating workdays or extra shifts to reduce the total number of employees on a job site at any given time to ensure physical distancing. The

recommendation for shifting individual employees should be at the sole discretion of the Local Business Manager or their Representative.

– Identify choke points where workers are forced to stand together, such as hallways, hoists and elevators, ingress and egress points, break areas, and buses, and put in place policies to

maintain social distancing.

– In elevators and personnel hoists, ensure six feet distance between passengers in all directions and equip operator with appropriate respirator and other personal protective equipment.

– Minimize interactions when picking up or delivering equipment or materials. Organize the placement of materials to minimize movement on the work site.

Decontamination:

– Clean and disinfect high-touch surfaces on job sites and in offices—such as shared tools, machines, vehicles and other equipment, handrails, doorknobs, and portable toilets—frequently,

per CDC guidelines.

– Make disinfectants available to workers throughout the worksite and ensure supplies are frequently replenished.

– Personal hygiene: Provide soap and running water whenever possible on all job sites for frequent handwashing. If it is not possible to provide running water, disclose the reasons to your workers.

Provide alcohol-based hand sanitizers with greater than 60% ethanol or 70% isopropanol as a backup only if providing running water is impossible. Encourage workers to leave their workstations to wash their hands before and after going to the bathroom, before eating, and after coughing, sneezing, or blowing their nose.

Respiratory protection:

If workers need to be near each other to perform tasks or when working in close quarters, such as confined space work, they should wear a NIOSH-approved respirator implemented under a full respiratory protection program. NIOSH-approved respirators include filtering facepiece and elastomeric negative or positive pressure half or full facepiece respirators equipped with

N95, N99, N100, R95, P95, P99, or P100 filters.

– Cloth face coverings are not respirators and do not replace physical distancing or respirators required when workers are in close proximity. However, cloth face coverings should be provided

in other circumstances when required or recommended by state or local governments.

• Work in healthcare facilities:

If you work in healthcare facilities, train your workers in Infection Control Risk Assessment (ICRA). For information on CPWR’s ICRA training program, visit here.

In response to the construction industry’s questions regarding the COVID-19 outbreak, the following are steps workers should be taking now:

• Don’t go to work if you are feeling sick.

• Don’t go to work if you have a fever.

• Don’t go to work if you have a cough or shortness of breath.

• Avoid contact with sick people.

• Don’t shake hands when greeting others.

• Avoid large gatherings or meetings of 10 people or more.

• Stay at least 6 feet away from others on job sites and in gatherings, meetings, and training sessions.

• Cover your mouth and nose with tissues if you cough or sneeze or do so into your elbow.

• Avoid touching your eyes, nose, or mouth with unwashed hands.

• Clean your hands often by washing them with soap and water for at least 20 seconds. When hand washing isn’t available, use an alcohol-based hand sanitizer with greater than 60% ethanol or 70% isopropanol. Soap and water should be used if hands are visibly dirty.

• Clean your hands frequently, including before and after going to the bathroom, before eating, and after coughing, sneezing, or blowing your nose.

• Bring food and water bottles from home to the job site and do not share.

• Drive to worksites or parking areas by yourself—no passengers or carpooling.

• Disinfect interiors and door handles of machines or construction vehicles, and the handles of equipment and tools that are shared following employer’s COVID-19 exposure control plan.

Special guidance for older workers and people with underlying health conditions:

• Older adults and those with underlying health conditions like heart disease, diabetes, and lung disease and those with compromised immune systems (such as lupus, rheumatoid arthritis, cancer therapy) are more at risk of becoming very sick from COVID-19. CDC has additional recommendations for these individuals at the link below:

o https://www.cdc.gov/coronavirus/2019-ncov/specific-groups/high-risk-complications.html.

Additional links from federal government sources:

• OSHA: https://www.osha.gov/SLTC/covid-19/

• NIOSH: https://www.cdc.gov/niosh/emres/2019_ncov.html

• CDC: https://www.cdc.gov/coronavirus/2019-ncov/index.html

• CDC for Employers about getting their businesses ready:

https://www.cdc.gov/coronavirus/2019-ncov/specific-groups/guidance-business-response.html

Please be aware that people are vulnerable in these uncertain times. If a colleague or coworker needs mental health or substance use care, they should contact their member assistance program, employee assistance program, or the National Suicide Prevention Lifeline: 1-800-273-TALK (8255) https://suicidepreventionlifeline.org or the SMOHIT Helpline at 1-800-662-HELP (4357)

Nineteen members participated in a two-day Copper Development Association (CDA) training class and a single-day ITI Procedure and Performance training/testing class Oct. 31-Nov. 1 in St. Louis in a concentrated effort to continue education and stay ahead of trending markets.

The CDA’s Soldering Techniques/Methods and Soldering Flat Seam Copper Metal Roof Installation Training provided members with technical knowledge and hands-on skills essential to soldering. It also allowed locals, contractors and industry partners to develop the standards used to qualify SMART members to do the work. Class topics included understanding requirements for soldering to American Welding Society (AWS) B2.3:2018 Specification for Soldering Procedure Performance Qualification Testing.

“First and foremost, it’s about training and education,” said Dan McCallum, ITI field representative. “Second, it’s more of a quality assurance program that the individuals doing this work are trained and certified. Otherwise, what do you know about the person completing the task? You don’t.”

A welding procedure specification (WPS) is a document that serves as a guide for the effective creation of a weld that meets all applicable code requirements and production needs. A performance qualification shows whether a welder possesses the necessary skills and knowledge to perform the specifications of a particular WPS.

During the class, one soldering procedure specification, Horizontal Flow, as well as two performance qualification tests (SPS #536-23/P and SPS #529-213/Cu) were submitted and qualified. All 19 participants passed/qualified on the available procedures and soldering positions. During the testing, two signatory contractors to St. Louis’ Local 36 witnessed the qualifications by employees of their respective companies.

SMART, its contracting partners and ITI work together to assure members are the first to be trained and qualified to complete the work. The ITI facilitates the test while SMART contractor partners develop the procedure, allowing formal recognized training and the ability to develop procedures and facilitate the test.

For additional information on this class and others, visit the ITI’s website course catalog at https://www.sheetmetal-iti.org/course-catalog.

SMART Sheet Metal Local 399 members Nick McLester, Marcus Vickers, Chris Hall (Business Manager), Larry Stewart, and Chris Brainard took off a recent February weekend to build a wheel chair ramp for Lutron Weeks.