The massive Ford Blue Oval battery plant in Glendale, Kentucky, is a case study in how megaprojects are driving growth and sparking new organizing in the unionized sheet metal industry. Local 110 (Louisville, Kentucky) has nearly doubled in size since January 2023, bringing hundreds of previously unorganized workers into our union to meet unprecedented workforce demands.

“It’s been a very successful effort, from the organizing — planning and implementing our strategy — to the workers getting on site and doing the work,” said Local 110 Recording Secretary and Organizer Jeremy Waugh.

“You’re going to have generations of sheet metal workers that come out of [this project], and they’re spreading the word,” added Local 110 Organizer Anthony Adams. “This area will become very union strong.”

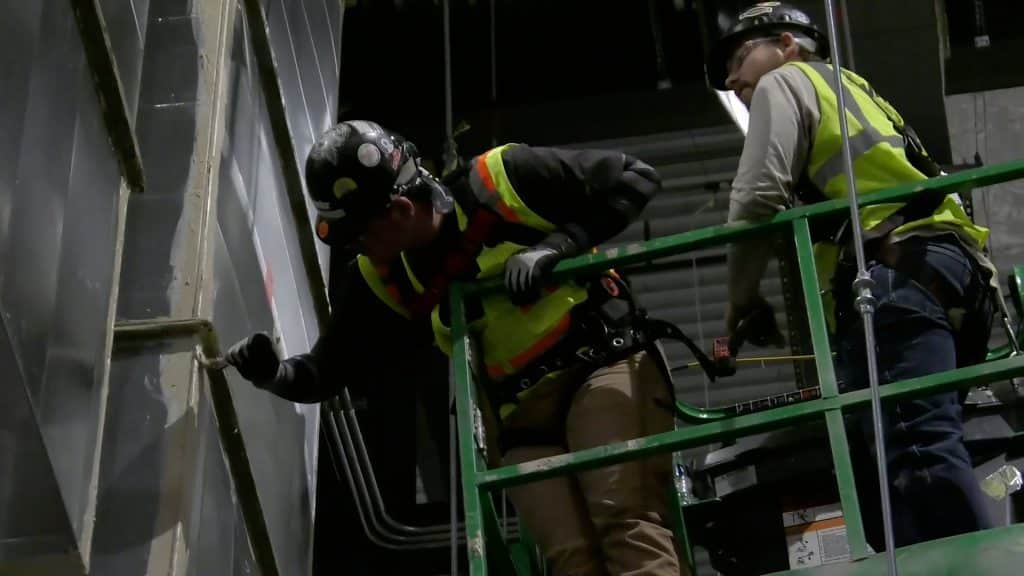

Once construction at Blue Oval is complete, the 1,500-acre battery park will be the largest in the world, consisting of two electric vehicle battery production plants and eventually employing thousands of workers. Local 110 members are currently installing roughly 37 miles of duct in the buildings — along with performing testing and balancing and architectural sheet metal work.

It’s a truly enormous job, explained site Superintendent and Local 110 member Ryan Mc Donaugh of Poynter Sheet Metal, who called it “the Super Bowl of sheet metal.” Poynter Sheet Metal Senior Project Manager and Local 110 member Andy Wright agreed.

“To me, it looks like this is part of the next industrial revolution,” he said.

Unions are working overtime to make sure this new industrial revolution is one that benefits workers, not just the CEOs of multinational corporations. That’s especially important in a right-to-work state like Kentucky, where organized labor has to beat back decades of misinformation about the union difference. From the moment Blue Oval was announced, Waugh said, the local treated staffing the project as an organizing drive, focused on strengthening the local and changing the lives of workers in the Bluegrass State.

So far, those efforts have been successful.

“I went nonunion right out of high school, so I was starting dirt cheap, no money at all,” recalled Local 110 journeyperson Chase Taylor. “The pay scale out here [in the union] is about double what I made at my old job.”

Taylor’s experience of joining the union and gaining a life-changing pay increase is one that the local hopes to extend to working people across Kentucky, Adams said, especially those from marginalized and underrepresented groups who may not have had access to good, union careers in the past.

“It’s prime time for us, in this state, to spread the word of what it means to be in a union, and what that gets you,” Waugh concluded.