Pictured, left to right: Evan Brown, Jerry Durieux, James Chester and Kevin Tesch at the 2022 Local 33 Akron District Retiree Christmas Party. Chester received his 50-year service award during the party. Congratulations, brother!

Pictured, left to right: Evan Brown, Jerry Durieux, James Chester and Kevin Tesch at the 2022 Local 33 Akron District Retiree Christmas Party. Chester received his 50-year service award during the party. Congratulations, brother!

SMART Northeast Regional Council President and General Vice President Robert Butler recently honored Local 17 (Boston, Mass.) member George Psaros for his 70 years of service to our union. Congratulations on this incredible achievement, Brother Psaros!

During a financial secretary-treasurers meeting at SMART International headquarters in Washington, DC, several SMART Rail, Mechanical and Engineering (RME) Department members received their 15-year service awards. Pictured, left to right: Erik Marro from Local 31 (Harmon, New York); Rob Ussery of Local 78 (Little Rock, Arkansas); SMART International Representative C. Joseph Fraley of Local 31; Rob Kaminskey from Local 149 (New York City); and Arnold Fernandes from Local 139 (Boston, Mass.).

SMART Local 33 (Cleveland, Ohio) officers and the third-year apprentice class gathered toys to donate to families in need as part of the Belonging and Excellence for All (BE4ALL) Pedal to the Metal Toy Drive. Each toy included a tag with a QR code that provides interested parents or guardians with information on entering a union sheet metal career.

SM Local 88 (Las Vegas, Nevada) won the first annual Southern Nevada Building Trades softball tournament. They forged a dominant run through a crowded field of 18 other teams, none of which were able to stand up to the hitting prowess and fielding only Local 88 could muster. Congratulations!

Local 17 (Boston, Mass.) members are preparing to begin work on one of the largest real estate projects in Boston history, as well as the largest-ever project labor agreement (PLA)-covered job in Massachusetts: the redevelopment of Suffolk Downs, a former horse racing site on the border of east Boston and neighboring Revere. The 20-year buildout is set to create pipelines to family-sustaining union careers for thousands of local community members, as well as construct affordable housing in the area.

According to the development firm heading the project, HYM Investment Group, “the redevelopment will transform 161 acres into a new resilient mixed-use neighborhood served by two stops on the MBTA Blue Line. Suffolk Downs will create 10,000 new units of housing to meet critical demand in the market, and will provide a mix of senior, workforce, family and young professional housing, including over 900 affordable units.”

And thanks to the PLA negotiated between HYM, its general contractor, John Moriarty & Associates and both the North Atlantic States Regional Council of Carpenters and Boston’s Building and Construction Trades Council, the Suffolk Downs project will be completely union-built and create 14,000 jobs across every sector of the building trades.

The initial project phase will include approximately 1.39 million square feet of development consisting of the Phase 1 Project (520,000 square feet of corporate use and amenity space); three residential buildings; a portion of the townhomes proposed along Waldemar Avenue totaling over 800 housing units; and construction of the Horseshoe Pond landscaped wetland enhancements and Belle Isle Square public plaza, with over 100,000 square feet of ground floor retail.

“It will be a city within a city,” said SMART Northeast Regional Council Labor Management Representative John Cody. “The local community will benefit from new affordable housing and pathways to new careers, whether it be in retail, hospitality, bio life science or the Boston building trades unions. And for our current members of Local 17, we are starting from a blank canvas, so the many hours of work generated by this project will sustain the quality of life for the families of Local 17 and other trades.”

The power of a union-negotiated project labor agreement is on full display with the Suffolk Downs job: Labor, with the help of former Boston Mayor Marty Walsh and Mass. State Senator (former City Councilor) Lydia Edwards, worked hard to ensure strong equity and local hire requirements are included in the project’s short- and long-term future.

As part of the PLA, HYM committed to providing $2 million in investments to support employment pipelines that will help local residents enter family-sustaining, union careers, both during construction and as part of Suffolk Downs’ future workforce. That includes $1 million in new funding to support the Building Pathways pre-apprenticeship program, in which 90% of enrollees are people of color and 43% are women, and allows direct employment of graduates from Building Pathways.

“Having this PLA in place will help with the growth of the local,” Cody concluded. “Through community standards in place within the PLA, our involvement with various community groups in the area, our outreach to trade schools and career fairs in the city and even on the grounds of the project itself provided by the developer and our partnership with them throughout this whole process. We are hitting the streets and visiting workers, letting them know what a union is all about.”

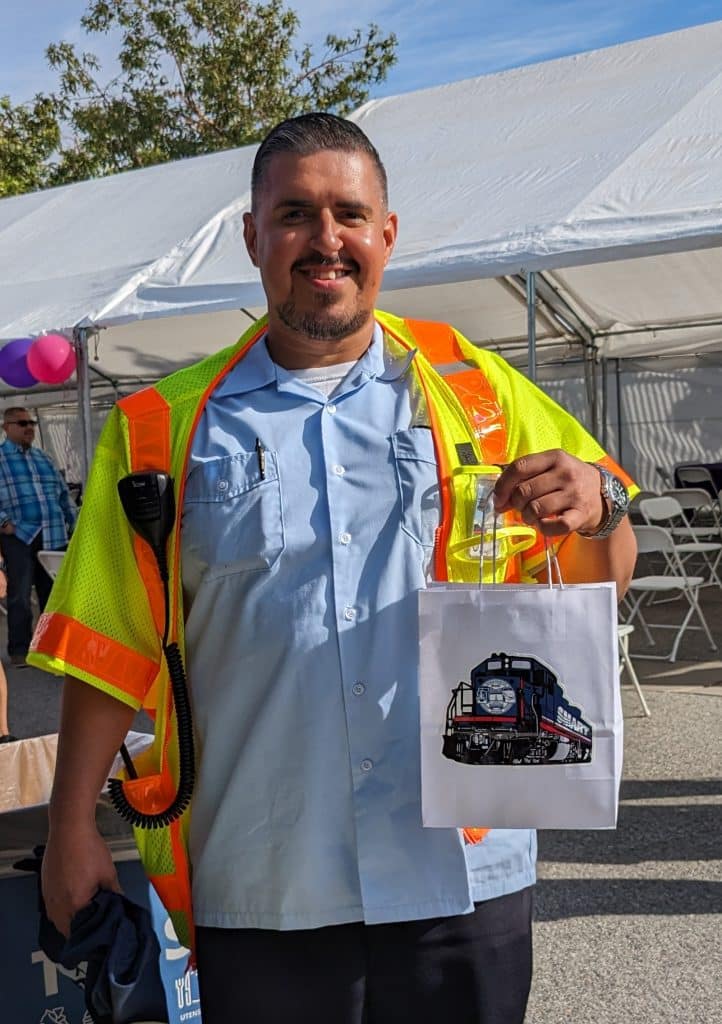

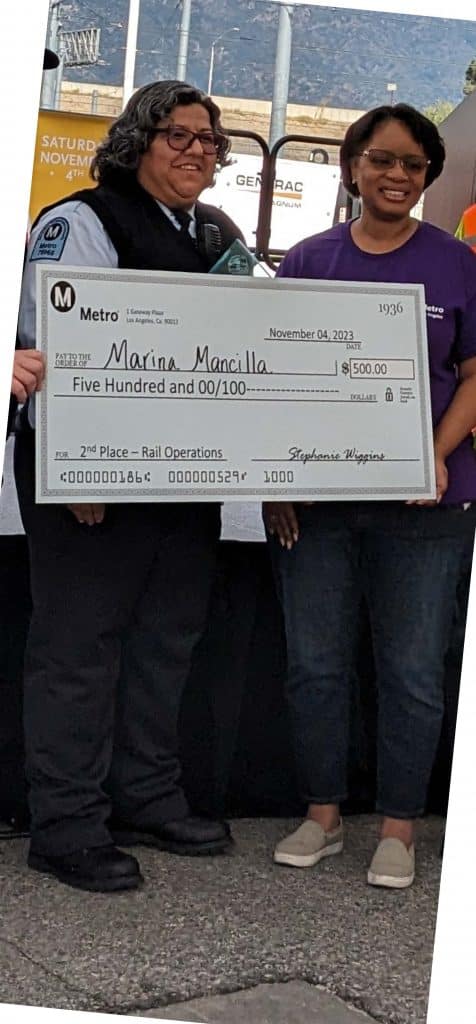

On Saturday, November 4, SMART-TD Local 1565 members working at Los Angeles Metro participated in the Monrovia division rail rodeo, competing with other transit rail workers and showing off the skills they use to transport passengers safely and efficiently every day. In addition to the skills competition, SMART-TD members and families showed out to support their union family, and Local 1565 set up a table representing SMART to fellow transit workers and potential members.

Carl Hackerott, a dedicated member of SM Local 16 (Portland, Ore.), passed away shortly before reaching the remarkable milestone of 70 years of service to his union. In honor of his many years of devoted trade unionism, Local 16 presented Hackerott’s 70-year service award to his wife.

“Not only was Carl a skilled and accomplished sheet metal worker, but he also found joy in reviving antique sheet metal equipment. In honor of his memory, the Hackerott family decided to generously donate a meticulously restored, 1896, four-foot wooden hand brake to the training center. It is on display in the lobby of our Portland campus,” the Sheet Metal Institute — Local 16’s training center — wrote on Facebook. “During the heartfelt presentation of this cherished artifact, Mrs. Hackerott was deeply moved as she received her late husband’s well-deserved 70-year pin.”

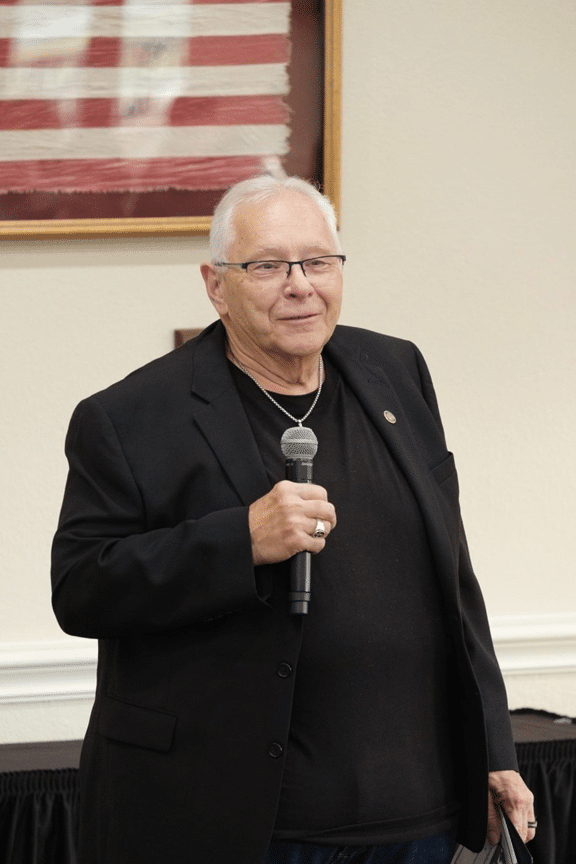

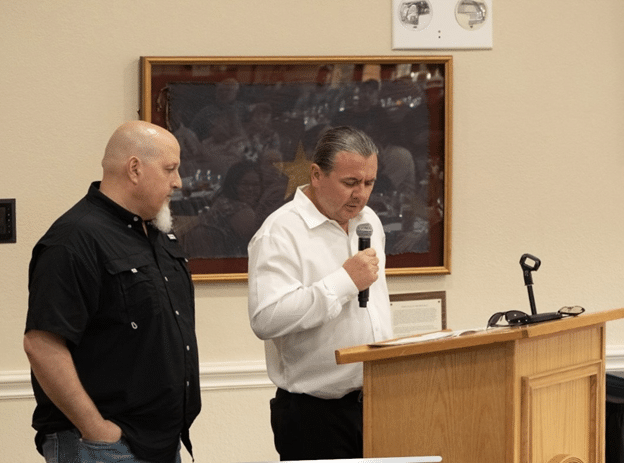

Local 68 (Dallas and Fort Worth, Texas) hosted its JATC Graduation and Pin Recipients Banquet on July 28, 2023, where local union leadership recognized the dedication of long-serving members and celebrated the newest journeyworkers in our union. Importantly, the ceremony gave newly graduated apprentices the chance to witness the lifelong benefits that SMART membership provides. Great work, Local 68.

This article was originally published on WNYLaborToday.com. Images courtesy of WNYLaborToday and Local 46.

When it comes to giving back to the Rochester, N.Y., community, the members and apprentices of SMART Local 46 are ready, willing and able to do what they can, when they can.

Case in point: Back in October, WNYLaborToday.com spotlighted SMART Local 46’s apprentices, who are playing a key role in helping provide a local nonprofit with a main cog needed to assemble hundreds of devices that give the life-changing gift of mobility to children with physical disabilities.

Now, many of the local’s apprentices are back at it — giving their time and skills at the Rochester & Genesee Valley Railroad Museum, where they’re working to restore an idled trolley car that once ran the rails in downtown Rochester many years ago.

Established in April 1899 (the local is getting ready to celebrate its 125th anniversary), Local 46 represents 425 active and 200 retired members, and provides the highest quality craftspersons — described as pre-eminent fabricators and installers — to its union contractors.

The local also has more than 100 apprentices in its training program.

“We’ve been sending 10 apprentices at a time, about forty in all, and they are loving it,” Local 46 Training Director Allen Mort told WNYLaborToday.com about the restoration work being done at the Railroad Museum. “They’re working on the car’s roof and their sheet metal paneling. This has been awesome — they’re working to preserve our local history.”

Museum President Otto Vondrak says Local 46’s apprentices are helping restore a trolley car that ran on the Rochester system from 1938 to 1956.

“We got it donated to us back in 1998,” Vondrak said. “It also has a wood interior, and it’s been sitting here for more than 20 years. Before Local 46 got involved, we were fundraising to get the money to repair, and it was being restored — incrementally.”

“This makes me feel proud,” said SMART International Organizer Warren Faust, who joined WNYLaborToday.com for a tour of the Railroad Museum with Mort, Vondrak and Jonathan Perna, a Local 46 marketing representative.

“You have to have a diverse skill set to do work like this, and most people just don’t know we have it,” Faust added. “This is giving everyone a sense of pride, and it ties in with the fact that we band together to help.”

Offering what it describes on its website as “the most unique museum experience in the greater Rochester area,” the Rochester & Genesee Valley Railroad Museum is a nonprofit educational organization that traces its roots back to 1937 as the Rochester chapter of the National Railway Historical Society, the third-oldest chapter in the organization.

Its purpose, according to Vondrak, is to educate the public on the technology, history and impact of Rochester’s railroad industry through the preservation, restoration and operation of railroad equipment — as well as the display of relevant historic artifacts and documents.

The mission of the museum is advanced through the preservation of rolling stock and locomotives, tools and equipment, documents, artifacts, photography and video.

In 1971, the museum group purchased an abandoned Industry Depot from the Erie Lackawanna Railroad with the goal of restoring it as a museum — and over the last 50 years, the organization has preserved more than 40 pieces of historic railroad equipment and built its own demonstration railroad to bring Rochester’s rich railroading heritage to life. In fact, the museum operates and offers train rides every month from April through December.

Vondrak tells WNYLaborToday.com he is “super excited” to have Local 46’s apprentices working to help restore the rail car.

“They’re helping preserve the railroad heritage for all to enjoy, and their expertise in metal-working was something we don’t have here. [Local 46’s apprentices] have the expertise to help get it over the finish line,” he said.

The museum has spent more than $100,000 to date to help pay for the majority of restoration work that needs to be done, added Vondrak, who knows his nonprofit is “literally saving hundreds of thousands of dollars” thanks to the work being donated by Local 46.

“They are doing it all right — the first time” he said.

For Local 46, such projects aren’t only the right thing to do for the community; they help raise public awareness of the important role unions play, both on and off the job.

“It’s baffling, the perception [the general public has about what labor unions and union members do] — you just never get a good answer, but there’s a lot SMART does to help people,” Perna said. “When people ask me, I say: ‘Sure, we’re going to get our apprentices involved, because they care.’ And our focus is to give people a better life.

“If you’re not in a union, you’re doing it wrong – you’re missing out on the benefits. I feel good for our members and our apprentices that we’ve given them these opportunities [to do good things across the Rochester community.”

According to Mort, Local 46 apprentices who have participated in the effort include: Rand Warner, Earl Delong, Hunter Angarano, John Bertolone, Karl Biedlingmaier, Robert Dettore, Anthony Hayslip, Matthew Olek, Alexsi Ortiz, Cody Pascalar and Richard Andrew Ross.